What is an SPM Machine A Deep Dive into Special Purpose Machines by Aryans Powertech

In today's competitive manufacturing world, there's no room for delays or errors. Customers expect products to be delivered faster, with better quality, and at lower costs. This pressure has pushed manufacturers to turn to automation. Among the most effective automation tools in use today are SPM machines.

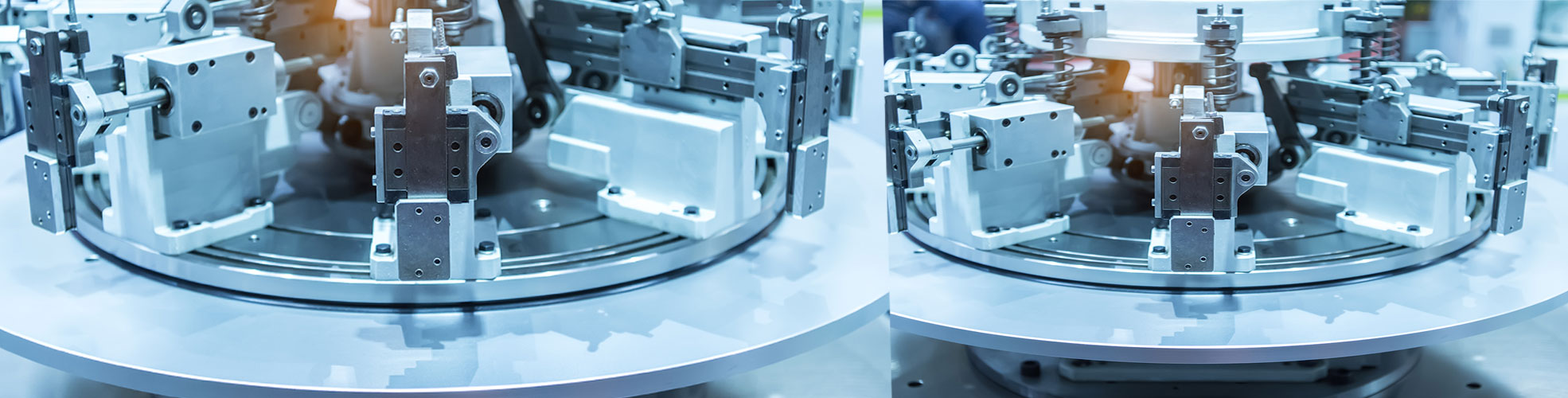

These machines, also called Special Purpose Machines, are designed for a single, repetitive task but do it far better than any human or general-purpose machine could. They are essential in sectors where volume, precision, and consistency matter the most.

In this blog, we cover everything you need to know about SPM machines—what they are, how they work, real-life examples, and how Aryans Powertech is helping Indian industries transform their production floors.

What is an SPM Machine? (SPM Machine Full Form)

SPM machine full form is Special Purpose Machine.

Usage & Working of Special Purpose Machines

Where are SPM machines used?

- In automotive industries for making gears, shafts, axles

- In electronics for soldering or assembling PCBs

- In FMCG for bottling, capping, and labelling

How does an SPM machine work?

- Material Feeding: The raw component is fed into the machine manually or through an automated feeder.

- Control Signal: A Programmable Logic Controller (PLC) sends signals to motors and actuators.

- Tool Operation: A tool (like a drill, cutter, or press) performs its job with precision.

- Sensors: These detect the position of the part, pressure levels, and any errors.

- Ejection: The completed part is automatically ejected or passed on to the next station.

This cycle repeats for every component, ensuring consistent quality and speed.

Examples of Special Purpose Machines

1. Gear-Cutting Machines

2. Broaching Machines

3. Lapping and Honing Machines

4. Boring Machines

Automatic Control in SPM Machines

- PLCs (Programmable Logic Controllers)

- HMIs (Human Machine Interfaces)

- Sensors (limit switches, proximity sensors)

- Servo Motors and Drives

These control systems automate operations like:

- Start/stop cycles

- Speed and torque regulation

- Safety interlocks

- Cycle time monitoring

For example, in an SPM drilling machine, the depth and speed of drilling can be set through the HMI panel. The machine adjusts itself automatically based on the material and tool wear.

Automatic control not only increases output but also reduces the dependency on highly skilled operators.

Advantages of Special Purpose Machines

Cost-Effective in Long Run: While the initial investment may be high, the return on investment is quick due to reduced labor and faster output.

Disadvantages of Special Purpose Machines

High Initial Cost: Custom design and setup can be expensive.

Limited Use: Can perform only one task. A new machine is needed for a new task.

Downtime Risk: A malfunction can halt the entire line since these machines often serve as bottlenecks.

Complex Maintenance: Requires skilled technicians to repair and maintain PLCs or custom tools.

Space Constraints: Some SPMs are large and need dedicated floor space.

Despite these, SPMs are an excellent investment for high-volume manufacturers.

How Aryans Powertech is Helping the Industry

- Custom-Built Machines: Every machine is tailored to meet the customer’s exact process.

- End-to-End Service: From consultation and design to installation and maintenance.

- Advanced Technology: Their SPMs use top-quality PLCs, drives, sensors, and HMIs.

- After-Sales Support: Includes AMC (Annual Maintenance Contracts) and training.

- Retrofit Solutions: They upgrade old machines with new automation to boost efficiency.

Whether it’s gear hobbing or automated paint line mixing, Aryans Powertech ensures speed, reliability, and industrial-grade quality.

FAQs

Q. What is the full form of an SPM machine?

Q. What does an SPM machine do?

A. An SPM machine automates repetitive tasks like cutting, drilling, pressing, or assembling. It removes the need for manual labor and helps maintain quality in mass production. It is designed to reduce human error, speed up production, and ensure product uniformity.

Q. Where are SPM machines used?

- Automotive: Engine blocks, gear assemblies

- Paint & Coating: Filling machines, mixer integration

- FMCG: Bottle capping, tube sealing

- Electronics: Soldering and PCB assembly

- Defense & Aerospace: Precision part manufacturing

Q. Are SPM machines programmable?

Q. Why choose Aryans Powertech for SPM machines?